This department also includes research in different fields of Petroleum Engineering.

Main directions of research activities are:

- Exploration, Production and Reservoir Engineering

- Enhanced Oil Recovery

- Natural Gas Engineering

- Non-Newtonian Systems Application in Petroleum Production

- Petroleum Geoscience

- Petrophysics

- Other Areas

Diverse academic disciplines of the department enable both research and training to be pursued in a multi-skill environment, which is essential to the modern oil and gas industry. The department has and will continue to pursue relevant research to meet the needs of the industry.

The Department has 2 laboratories and they are used for educational and research purposes:

1. Petroleum and gas engineering training and research laboratory

2. Oil and gas fields simulation laboratory

“Petroleum and gas engineering training and research laboratory” of the Department of Petroleum Engineering has well equipped with lab tools for teaching and learning of the fundamentals of Petroleum and Gas Engineering. They are also used for graduate, postgraduate research and industrial consultancy work. The laboratory was equipped with the following types of equipment:

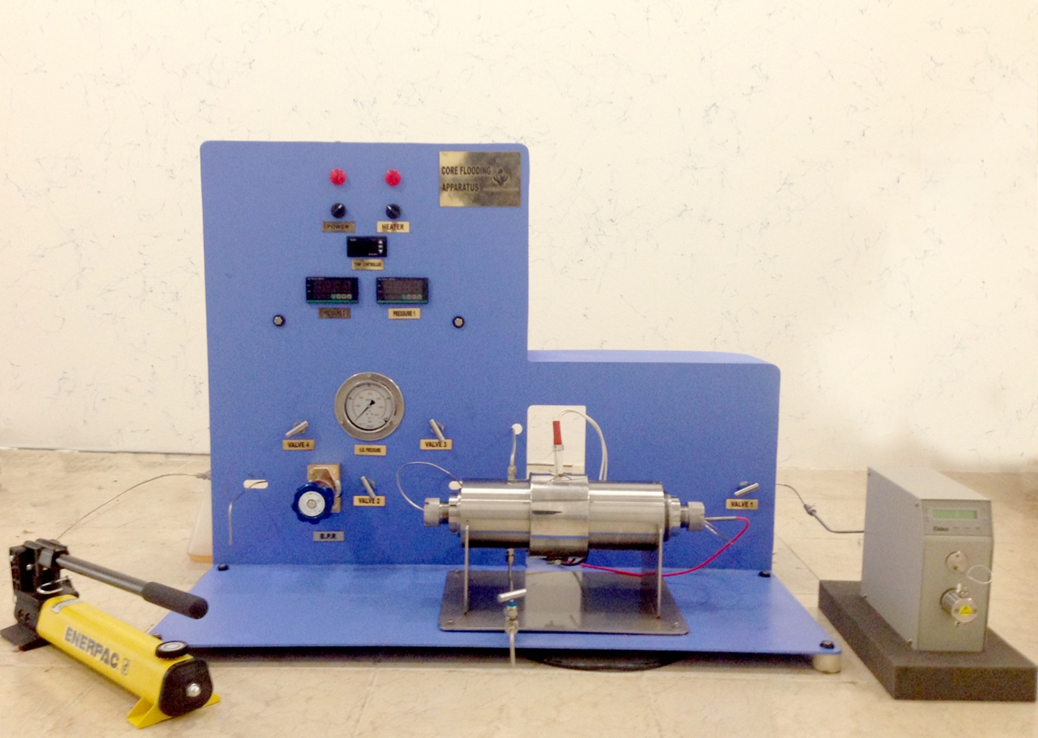

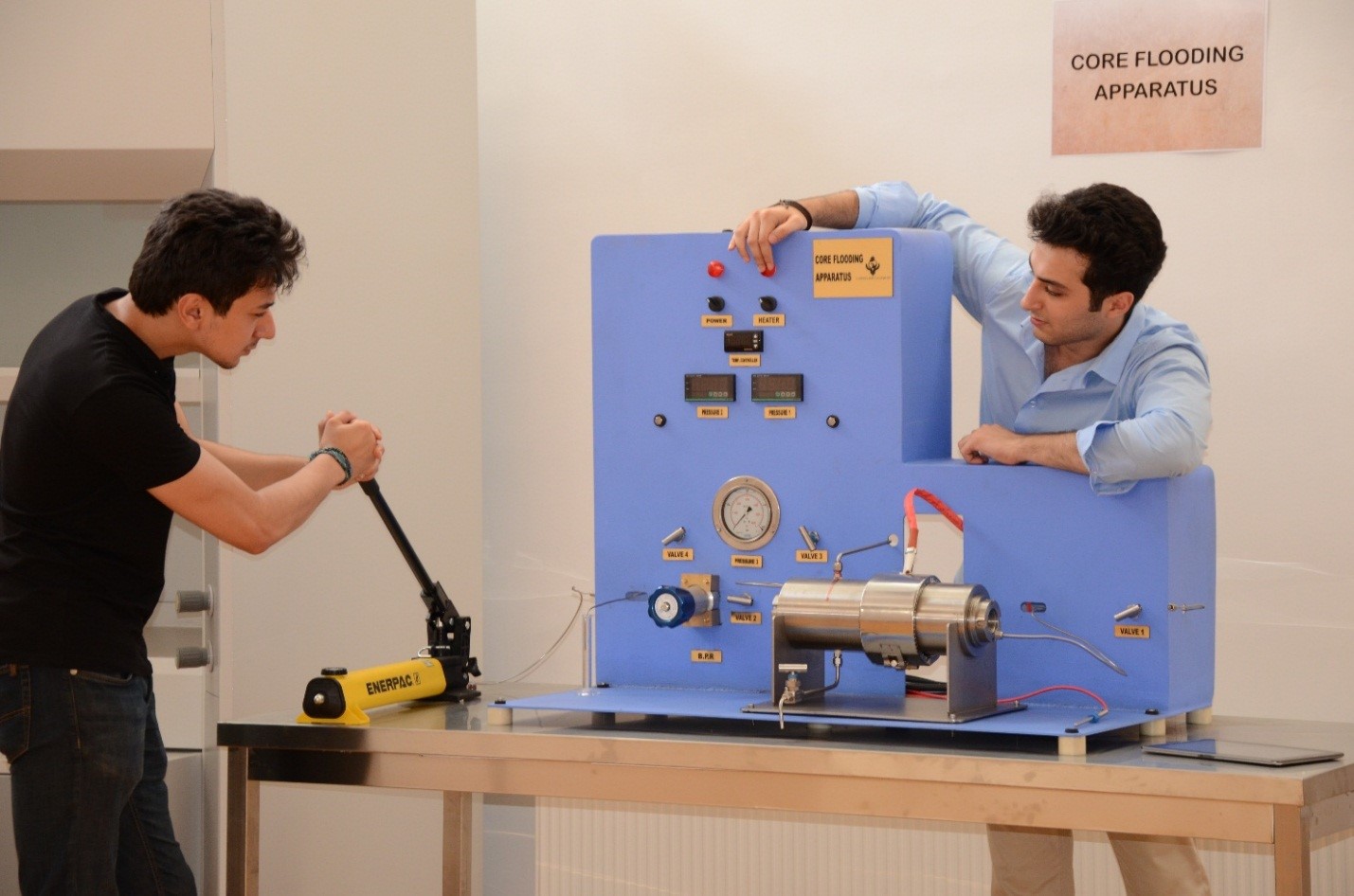

CORE FLOOD SYSTEM

A core flood system as the main part of the Petroleum Engineering training & research laboratory is used in experiments related to education and research processes in Petroleum Engineering. It is a system in which a liquid flows through a core sample at controlled pressure and temperature conditions. Different flow parameters are measured and monitored. Several types of experiments such as conventional fluid injection, chemical flooding, MEOR and permeability measurement at reservoir conditions could be performed with this apparatus. This is consists of a core holder that encloses the core sample and subjects it to simulated reservoir conditions. It allows rapid installation or removal of core samples.

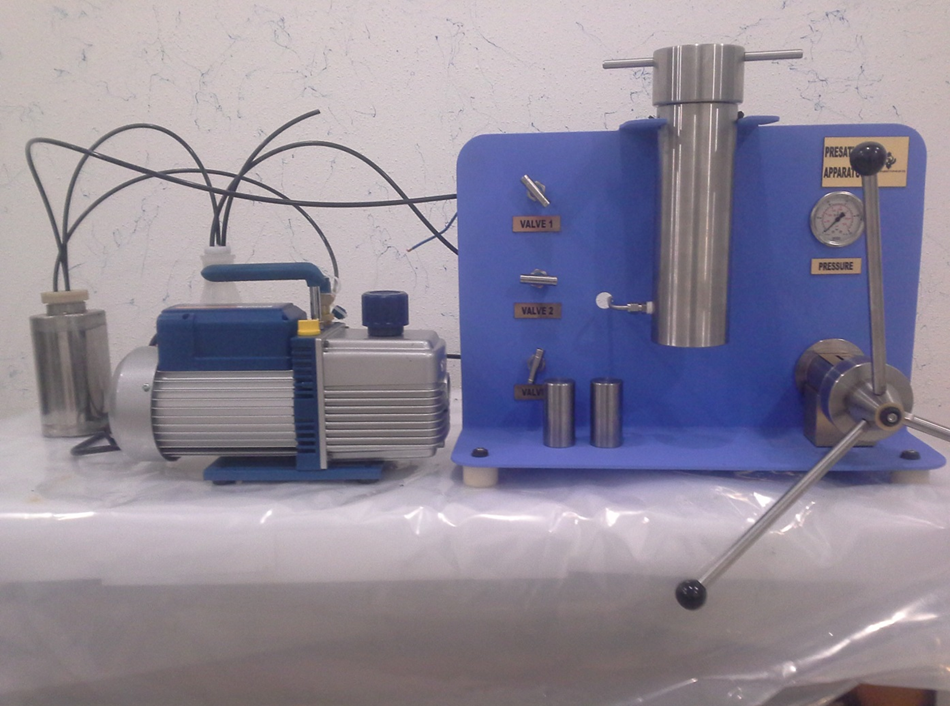

MANUAL SATURATOR

The manual saturator permits to perform a sequence of vacuum and saturation cycles on plug size samples for laboratory researches on analysis of oil and gas reservoirs properties by students. The apparatus includes a plug sized core cell, a vacuum pump, a hand operated pressure pump, a saturant vacuum vessel, and necessary hand-operated valves and pipelines. As saturation of core plug is used water, brine, oil or other liquids for evaluation of reservoir porous media and its relative permeability.

RECOMBINATION CELL APPARATUS

This instrument composed of high pressure and high-temperature recombination cell in which oil and gas samples from wellhead separator are injected in a pre-defined volume, heated at a desired temperature and pressurized at a pressure above the saturation pressure of the reservoir for few hours to give a homogenous mixture of the initial reservoir fluid. This lab instrument is used for fluid flow researches in different temperatures and pressure conditions on the development of oil and gas fields. The instrument comes with a recombination cell jacketed with a heating mantel for temperature control, two displacers and a manual pump. Recombination of separator or surface fluids to obtain recombined reservoir fluid.

HEAT EXCHANGER

This unit consists of a heat exchanger with a transparent cylindrical shell that allows visualization of the inside construction of the exchangers. One fluid flows through the tubes and the other flows through the shell. The aim of this experiment is that students can calculate the overall heat transfer coefficient (U) for shell and tube heat exchangers and investigate the effect of liquid flow rate on it. Several ball valves are used to run the experiment in co-current or counter-current modes to let students compare these modes. Using these valves, the hot or cold liquid can also flow through the tubes or through the shell so that students can realize when the hot fluid flows through the tubes, the heat loss becomes less. Using 4 thermocouples measuring the inlet and outlet temperatures of the hot and cold liquid, the log mean temperature difference (LMTD) can be calculated for co-current and counter-current flow mode. There are two ball valves used to control the flow rate of the hot and cold liquid to investigate the effect of flow rate on the overall heat transfer coefficient. The apparatus is mainly capable of performing different experiments at the thermal fluid condition:

- Increasing Heat Exchanger performance

- Study of heat transfer coefficient

- Study of the fouling factor in Heat Exchanger

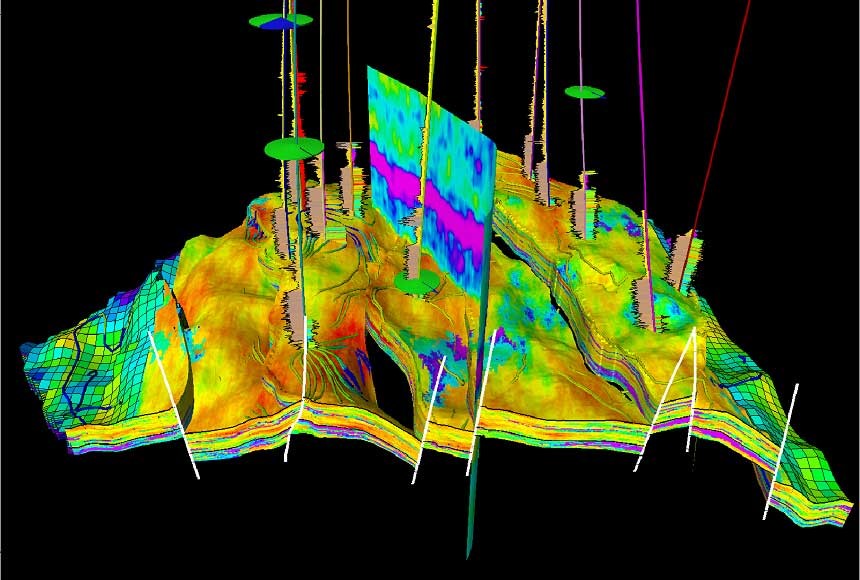

“Oil and Gas fields Simulation Laboratory” of the Department of Petroleum Engineering was established in 2011. Software packages (MATLAB, Eclipse, Petrel, etc.) are used in the Oil and Gas Fields Simulation Laboratory at the Department of Petroleum Engineering for academic and research purposes. Software packages are used for reservoir simulation of oil and gas fields, enhanced oil recovery methods, petroleum production technology and etc. These software packages currently are implemented in practical/lab classes of major courses and in conducted research works.